Antistatic, static electricity, dust and particle problems

Main menu:

Antistatic bars for discharging

Products > Antistat_list

Antistatic Bars

The most common component in the installation of antistatic equipment is undoubtedly the antistatic bar.

To choose correctly from different types of antistatic bars it is necessary to consider the conditions and possible constraints for the installation. The efficiency of an ionizing equipment depends on the distance between the equipment and material surface to be discharged as well as the speed. As a general rule it can be said that by shorter distances and moderate speeds single row bars are being used. With increasing speeds and distances double row antistatic bars are being used while finally applying air blowing antistatic bars.

Blowing antistatic bars are used with great success in applications where one needs to remove unwanted particles such as dust, dirt, chips, lint, fibers, etc. from the material surfaces. The blowing air acts both as a carrier for charge to discharge the area and mechanically to blow the particles away from the surface.

ABAC11 is a single row antistatic bar which is used for discharging static electricity from surfaces. Typical applications are discharging of sheets or webs in printing, converting, packaging, plastics production etc where materials cannot be processed or moved due to electrostatic charge.

Another important area of application is the cleaning of surfaces which cannot be satisfactorily cleaned due to dust and dirt particles being electrostatically attracted to the surfaces.

Antistatic bars are built to customers specifications and can be delivered in a self supporting design up to a length of 3 meters.

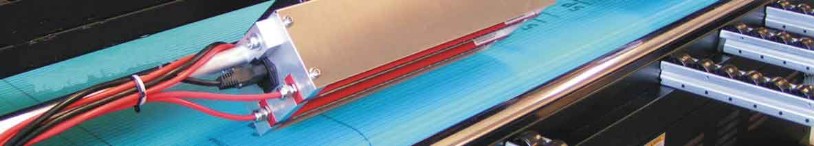

The casing of red anodized aluminum allows the electrodes to be completely shielded in three directions and the shielded cable HVC11 ensures a smooth installation of the power unit to the electrode.

ABAC11 has a compact design with a cross section of 15x30mm. The bars have threaded mounting holes for M6 at each end to easily be mounted eg by means of mounting bracket MBM11.

The shielded high voltage cable HVC11 are interchangeable and can be supplied in standard lengths or adapted in place of the current assembly. Antistatic bars are connected to a power unit in the series PUAC. For applications where the distance to the current material surface becomes too large or the speed is too high, it may be advisable to use a two-row antistatic bar ABAC21. For applications where you would like further wider range, it is recommended to use an air blowing antistatic bar ABACA21 or ionization fan IFAC11 or IFAC21.

ABAC21 is a double row antistatic bar which is used for discharging static electricity from material surfaces.

Typical applications are discharging of sheets or webs in printing, converting, packaging, plastics production etc where materials cannot be processed or moved due to electrostatic charge.

Antistatic bars are built to customers specifications and can be delivered in a self supporting design up to a length of 3 meters.

The casing of red anodized aluminum allows the electrodes to be completely shielded in three directions and the shielded cable HVC11 ensures a smooth installation of the power unit to the electrode.

ABAC21 has a compact design with a cross section of 30x30mm. The bars have threaded mounting holes for M6 at each end to easily be mounted eg by means of mounting bracket MBM11.

The shielded high voltage cable HVC11 are interchangeable and can be supplied in standard lengths or adapted in place of the current assembly. Antistatic bars are connected to a power unit in the series PUAC.

For applications where you would like further wider range, it is recommended to use an air blowing antistatic bar ABACA21 or ionization fan IFAC11 or IFAC21.

The blowing bar ABACA21 is a two-row antistatic bar, which has two rows of ionization pins and an integrated air channel for blowing with compressed air. Blowing antistatic bars are used for applications where ionization is combined with compressed air. Ionized air is frequently used for picking / stacking of products which would otherwise "stick" together, such as printing presses, vibration feeding, assembly of finished parts in trays such as: for injection molding, tabletting and product inspection, at tube filling, with pastes, creams, powders, etc.

The blowing antistatic bar ABACA21 is used for purging in electronics, optics, plastic industry as well as in printing and coating facilities. In combination with vacuum ramps, ABACA21 is used for line clearance applications, vacuum cleaning of glass, cardboard and plastic sheets, etc.

In applications where antistatic bars can not be placed within a short distance due to moving machine parts e.g. roll changer it is recommended to use the air blowing bar ABACA21.

The antistatic bars are built into custom lengths in a self-supporting construction up to 3m length. The casing of red anodized aluminum allows the electrodes to be completely shielded in three directions and the shielded cable HVC11 ensures smooth installation of the power unit to the electrode. ABACA21 is a compact design with a cross section of 30x30mm. The bars have threaded mounting holes for M6 at each end to easily be mounted eg by means of mounting bracket MBM11. The shielded high voltage cable HVC11 is interchangeable and can be supplied in standard lengths or adapted in place of the current assembly. Compressed air is connected to the air nipples at the short end of the bar or to nipples on the back page piece of the bar by 6 mm pneumatic tubing. The bars are preferably powered by a power unit type PUAC114 for AC voltage of 4-5 kV AC.