Antistatic, static electricity, dust and particle problems

Main menu:

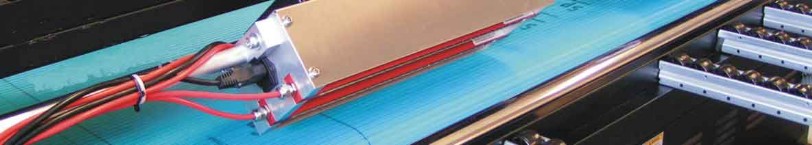

Swedish Electrostatics AB is specialized in problem solving and system solutions in static electricity

![]() We offer products and services that help customers to increase quality and capacity resulting in increased profitability and in many cases, safer and more pleasant working environment for operators and other production personnel. A wide range of products with equipment for dischagring and charging with static electricity, enabling a rapid response by the customer. Swedish Electrostatics uses specialized tools to evaluate and describe problems and quality assurance by measuring the electrostatic properties of materials or antistatic problems.

We offer products and services that help customers to increase quality and capacity resulting in increased profitability and in many cases, safer and more pleasant working environment for operators and other production personnel. A wide range of products with equipment for dischagring and charging with static electricity, enabling a rapid response by the customer. Swedish Electrostatics uses specialized tools to evaluate and describe problems and quality assurance by measuring the electrostatic properties of materials or antistatic problems.

For more information about static electricity.

Static electricity often occurs as a hidden disturbance in production processes, with seemingly inexplicable random errors and disturbances. The hidden static problems are usually due to machines and processes are running at reduced speed and / or the presence of dust and unwanted particles may interfere with the process.

Our clients consist of companies that process or handle at least one component which is an insulator. This means that we have customers in most industries, from steel mills to bakeries. Even the companies that seemingly ought to escape static problems usually handle non-conducting packing materials, or have dust or health problems with unwanted particles that are electrically charged.

We tailor the needs of application solutions of equipment problems that can not be solved with standard equipment.

Do not hesitate to contact us for a constructive discussion about your process or production problems. Problem description should be illustrated with photographs, drawings or sketches so that we quickly can gain insight into the issue and provide a basis for appropriate action.

Please contact us so we can share with you how we can help you

Sincerely,

CEO, Reinhold Rutks

info@swedishlelectrostatics.se