Antistatic, static electricity, dust and particle problems

Main menu:

Special electrodes for pipelines

Products

Special Electrodes

To eliminate phenomenon as electrostatic charging in piping systems radial antistatic electrodes with blowing function are efficient investments for electrostatic discharging of product, minimizing "carry over" effects, or inhomogeneity of the product as particle distribution.

REACA11 is a ring electrode that eliminates static charging generated by transporting garnulate, powder, fibres an other bulk material in a piping system.

After installation of REACA11 in a piping system the risk for unexpected shutdowns in succeeding unit operations, caused by contamination (carry over), is reduced. The filling process can now be done with higher precision and accuracy than before.

Typical applications are at the outlet of cyclones and bulk containers, dispensing and filling equipments and more.

The ring electrode REACA11 is an annular ionising nozzle designed to be easily fitted into existing piping systems. The electrode is powered by high-voltage transformer PUAC114 alt. PUAC214AL and connected to existing compressed air of approximately 0.5 - 1.5 bar. By blowing ionized air across the material flow an effective discharging of the material flow is obtained. The unit can be ordered for various pipe sizes.

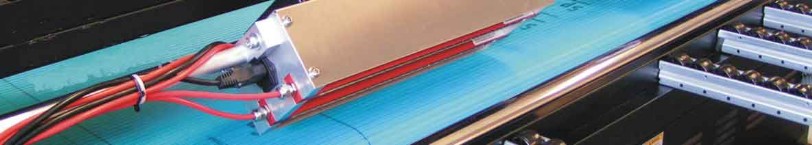

IBN53TH-13AC is an electrode particuarly suitable for tube filling of liquids, suspensions, pastes and creams in cases where the weld is not completely sealed. The advantage of applying the electrode to a tube filling process is higher accuracy and lower risk for production stops.

The electrode is available in different diameters and can be adapted easily to customer needs.