Antistatic, static electricity, dust and particle problems

Main menu:

Charging Electrodes

Products > Charging_list

Charging Electrodes

Charging electrodes differ in one important respect from the antistatic bars / electrodes in that they do not have their own built-in ground plane.

On the contrary, they are designed not to have any have no interfering ground plane in presence in order to function efficiently and controllably. Standard electrodes are in the shape of point charging electrodes PCEHV11 and bar-shaped charging bars CBHV11 which are made up of selfsupporting insulating material. For special applications cutomer specific electrodes can be made as e.g. in mold labeling / decorating where the electrode is designed to pick the label by means of vacuum and with a robot to place the label into the mould and electrostatically stick the label to the mould of the injection moulding machine.

All the electrodes, both standard and tailor made are made with integrated current limitation to minimize the risk of sparkovers to personnel to machines, or materials handled due to repeated sparkovers.

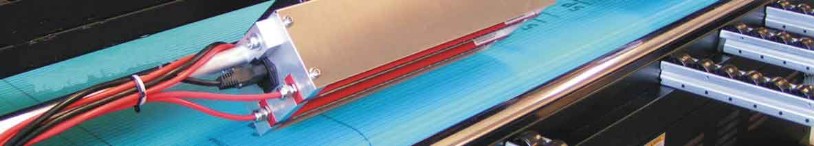

The charging bar CBHV11 together with point charging electrode PCEHV11 are standard electrodes for charging technology.

The electrodes are powered by high voltage generators in series PUHV30 or PUHV15.

Charging equipment is being used in most sectors of industry for an ever-increasing number of applications where you want to charge one or more materials electrostatically in controlled manner. Some typical examples are, electrostatic pinning of book blocks in book binding, pinning down the tail in production of bags on rolls, laminating of chip board, pinning of printed matter and shrink film in mailing machines, enhanced contact between webs and cooling cylindres, etc

Charging bars are used either connected to a one polarity in where the electrostatic field is directed towards an groun potential or charging bars opposite polarity which are pointed against each other thus creating an electrostatic field. The charging bar CBHV11 is made of a shell of glass fibre reinforced epoxy resin with pins and current limiters embedded in epoxy resin. Bars are made according to customer specification in lengths up to 2m and painted blue.

Electrodes are connected via the shielded high voltage cable HVC11 which is normally integrally cast. The shield is cut of the electrode to avoid brake down at the end of the bar. A nylon cable gland with integrated strain relief and protective bending support ensures a safe connection. Electrodes with a interchangeable cable are made against specification.

The point charging electrode PCEHV11, together with the charging bar CBHV11 are standard electrodes for charging technology. The electrodes are driven by the high-voltage generators in series PUHV30 or PUHV15.

Charging equipment is being used in most sectors of industry for an ever-increasing number of applications where you want to charge one or more materials electrostatically in controlled manner. Some typical examples are, electrostatic pinning of book blocks in book binding, pinning down the tail in production of bags on rolls, laminating of chip board, pinning of printed matter and shrink film in mailing machines, enhanced contact between webs and cooling cylindres, in mould labelling etc

Charging electrodes are used either connected to a one polarity in where the electrostatic field is directed towards an groun potential or charging bars opposite polarity which are pointed against each other thus creating an electrostatic field. The point charging electrode PCEHV11 is made of a shell of glass fibre reinforced epoxy resin with pins and current limiters embedded in epoxy resin.

Electrodes are connected via the shielded high voltage cable HVC11 which is normally integrally cast. The shield is cut of the electrode to avoid brake down at the end of the electrode. A nylon cable gland with integrated strain relief and protective bending support ensures a safe connection. Electrodes with a interchangeable cable are made against specification

.